Next to do is order the parts and solder these things up! Then software time and debugging... Stay tuned!

Ken's Projects Blog

Saturday, April 20, 2013

PCBs are in!!!

So I finally received the PCBs for my remote application controller project. Again I ordered these from Sparkfun's batchpcb.com. It took about 3 weeks total from payment to my door. I paid about $45 total for 1 board of each, but I guess there must have been extra room on the panel or something because they sent me 2 of the receiver (large board) and 4 of the transmitter (tiny board)! I can't really complain about that. The quality is pretty good, not the best I've ever seen, but not bad for the price you pay. Thanks BatchPCB!

Friday, March 29, 2013

PCB Ordering Time for my Remote Appliance Controller Project

So I finally managed to find the time to finish up the first prototype design up this project. If you want to know more what it's about read the previous posts below.

Anyways, I decided to go with sparkfun.com's BatchPCB service. I've heard only good things about it and it seems hard to beat the price so I figured I would give it a try. If you're unfamiliar with the outfit, it is a low cost prototype PCB service run my the famous Sparkfun. It costs $2.50 / sq. in. for a 2-layer board or $8 / sq. in. for 4-layer boards (plus a 1 time per order $10 setup fee). The way they manage to offer these low prices is by panelizing the different PCB designs that their customers submit and when a panel is full they send it off to a fab house that they do business with. The disadvantage is that your design will usually wait a little while until the panel fills up. However, it's hard to beat the prices for single quantities. My first board below only cost around $5! The second was was $20 because it is quite larger, but it's still quite a good deal.

Anyways, I decided to go with sparkfun.com's BatchPCB service. I've heard only good things about it and it seems hard to beat the price so I figured I would give it a try. If you're unfamiliar with the outfit, it is a low cost prototype PCB service run my the famous Sparkfun. It costs $2.50 / sq. in. for a 2-layer board or $8 / sq. in. for 4-layer boards (plus a 1 time per order $10 setup fee). The way they manage to offer these low prices is by panelizing the different PCB designs that their customers submit and when a panel is full they send it off to a fab house that they do business with. The disadvantage is that your design will usually wait a little while until the panel fills up. However, it's hard to beat the prices for single quantities. My first board below only cost around $5! The second was was $20 because it is quite larger, but it's still quite a good deal.

I will post again when I receive the boards with pics and then hopefully soon after that I can start assembly and MCU program development.

Sunday, February 10, 2013

Remote appliance controller update

So an update on the remote appliance controller project. I have been busy with school and work so I didn't have a lot of time to work on it over the last couple of weeks. However, this weekend I got a change to lay out the second board (transmitter/remote control).

Here is the transmitter board I just layed out:

Now I just need to check everything over well and I think I will order these boards from sparkfun.com's batchpcb.com. I've never used their service but it seems like a pretty good deal for small quantity boards. Check back soon for updates!

Here is the transmitter board I just layed out:

The challenge of this is that this board is really small. The mistake I made with the first board is I didn't choose an enclosure first. For this board I chose a small enclosure and create the mechanical outline of the board first. Then the challenge was to route everything. This board is only about 2.25 x 1.25 in! To make things worse it has a battery holder (which is mounted on the bottom) so that prevented me from putting any vias other than ground in that area.

As I mentioned I didn't choose a enclosure before designing the receiver board, so I had to find a bigger one and modify the board to fit it:

Just to get a perspective on the size of these things:

Wednesday, January 2, 2013

Remote Appliance Controller

Well recently my mom asked if I could build an electronic device for her. Out in her shed my step dad built some mangers for our dogs (one of my dogs just passed away unfortunately) in order to keep them warm during the winter. They have woodchips, insulation and haat lamps over them to keep them warm. Every time my mom wants to turn it on or off she has to go all the way out to the shed. My plan is to build a device that will allow her to remotely control the lights (and radio they have plugged in for the dogs).

So far I have worked on the controller/receiver board and am almost done with the PCB design. I have altium at my job and they let me use it when I want so I decided to do this project in altium in order to get a better handle on it.

This design uses a transformerless power supply. I decided to use a TI MSP430 microcontroller and a Microchip MRF49XA transceiver chip that I plan to run at 433 MHz. All it needs now is some mounting holes and a proper antenna (probably going to do some kind of onboard trace antenna).

I will post the transmitter PCB soon and the schematics for both.

So far I have worked on the controller/receiver board and am almost done with the PCB design. I have altium at my job and they let me use it when I want so I decided to do this project in altium in order to get a better handle on it.

This design uses a transformerless power supply. I decided to use a TI MSP430 microcontroller and a Microchip MRF49XA transceiver chip that I plan to run at 433 MHz. All it needs now is some mounting holes and a proper antenna (probably going to do some kind of onboard trace antenna).

I will post the transmitter PCB soon and the schematics for both.

Saturday, December 22, 2012

Hello Again with FPGAs

Hello again it's been a while since I have posted. I have been quite busy over this past year. I finished a electrical engineering co-op/internship with ITW Dynatec (June 2011 - January 2012 and May 2012 - August 2012) as well as two more semesters of electrical engineering. I am heading into my final semester in electrical engineering in January. Since I last posted I now also have a wonderful Peruvian girlfriend named Rosela (August 24, 2011) (http://attorneyatlaw-rosela.blogspot.com/)

Anyways since then I haven't really had time for a lot of projects due to how busy I was in a school these last two semesters but now I will have more time so I have started messing around with FPGAs. I got this nice little FPGA board from digilent:

and have been messing around with it doing some small projects. It's a nice affordable board for learning FPGAs and I highly recommend it for anyone interested in learning along with this course:

Well I have several ideas for some projects I want to do so I will post them as they come along...

Tuesday, March 1, 2011

My attempt at screen printing

I had been reading about this topicafter hearing the term used in PCB production "silkscreen" layer. Silk screening is a process used in the industry to print logos or graphics on tshirts, bags, balloons, circuit boards (silkscreen labels), etc (http://en.wikipedia.org/wiki/Silk_screen). Using this method I could create my own tshirts and custom logo clothing, and for dirt cheap!

Anyhow as I said before this is a projects blog not just electronics projects so I thought I would post it here. If you don't want to read that wikipedia article on screen printing I'll explain the basic principle. Basically a fine mesh material is used as a type of stencil. The stencil is created by blocking off the parts of the mesh where you don't want the ink to touch. Wherever you want ink to go (the "open" part of the stencil" you leave unblocked. Now there are many methods to do this including photo emulsion techniques but the technique I used was the good beginner's one explained here:

http://www.instructables.com/id/D.I.Y.-Screen-Printing/

I began by going to the good will, finding a flat front picture frame ($1):

and a meshy silky fabric (curtains) that were like $4.

I removed the photo matte and glass and using a staple gun stapled a piece of the fabric tight over the front of the frame like canvas for a painting.

Next I chose my image and used a pencil to trace it onto the "silkscreen."

I used yellowcard's new logo for their new album that is about to come out since I don't have any yellowcard shirts and I like them.

Here's the rest of my supplies. I used a paint bursh to brush the "mod podge" glue stuff onto anywhere I didn't want ink to go through creating a stencil.

After it dried it looked like this:

Now I'm ready to print. I set the stencil on top of my blank t-shirt with cardboard between to keep it from bleeding, spooned a little bit of the yellow dye/paint onto the stencil and using a squeegee ran it across the stencil. After that I removed the stencil and used an iron to warm and dry the ink.

Here is the finished result! Not too shabby! Pretty good for a first try!

Next time I'll try photo emulsion as it is more intricate and usually turns out better.

Anyhow as I said before this is a projects blog not just electronics projects so I thought I would post it here. If you don't want to read that wikipedia article on screen printing I'll explain the basic principle. Basically a fine mesh material is used as a type of stencil. The stencil is created by blocking off the parts of the mesh where you don't want the ink to touch. Wherever you want ink to go (the "open" part of the stencil" you leave unblocked. Now there are many methods to do this including photo emulsion techniques but the technique I used was the good beginner's one explained here:

http://www.instructables.com/id/D.I.Y.-Screen-Printing/

I began by going to the good will, finding a flat front picture frame ($1):

and a meshy silky fabric (curtains) that were like $4.

I removed the photo matte and glass and using a staple gun stapled a piece of the fabric tight over the front of the frame like canvas for a painting.

Next I chose my image and used a pencil to trace it onto the "silkscreen."

I used yellowcard's new logo for their new album that is about to come out since I don't have any yellowcard shirts and I like them.

Here's the rest of my supplies. I used a paint bursh to brush the "mod podge" glue stuff onto anywhere I didn't want ink to go through creating a stencil.

After it dried it looked like this:

Now I'm ready to print. I set the stencil on top of my blank t-shirt with cardboard between to keep it from bleeding, spooned a little bit of the yellow dye/paint onto the stencil and using a squeegee ran it across the stencil. After that I removed the stencil and used an iron to warm and dry the ink.

Here is the finished result! Not too shabby! Pretty good for a first try!

Next time I'll try photo emulsion as it is more intricate and usually turns out better.

Wednesday, February 9, 2011

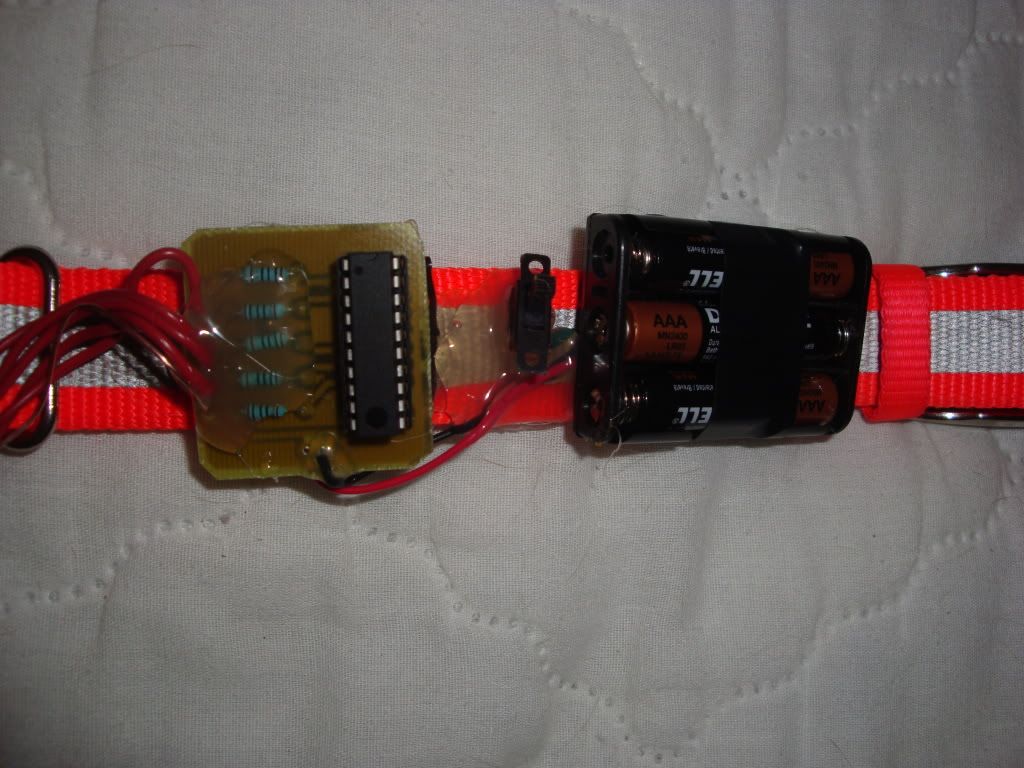

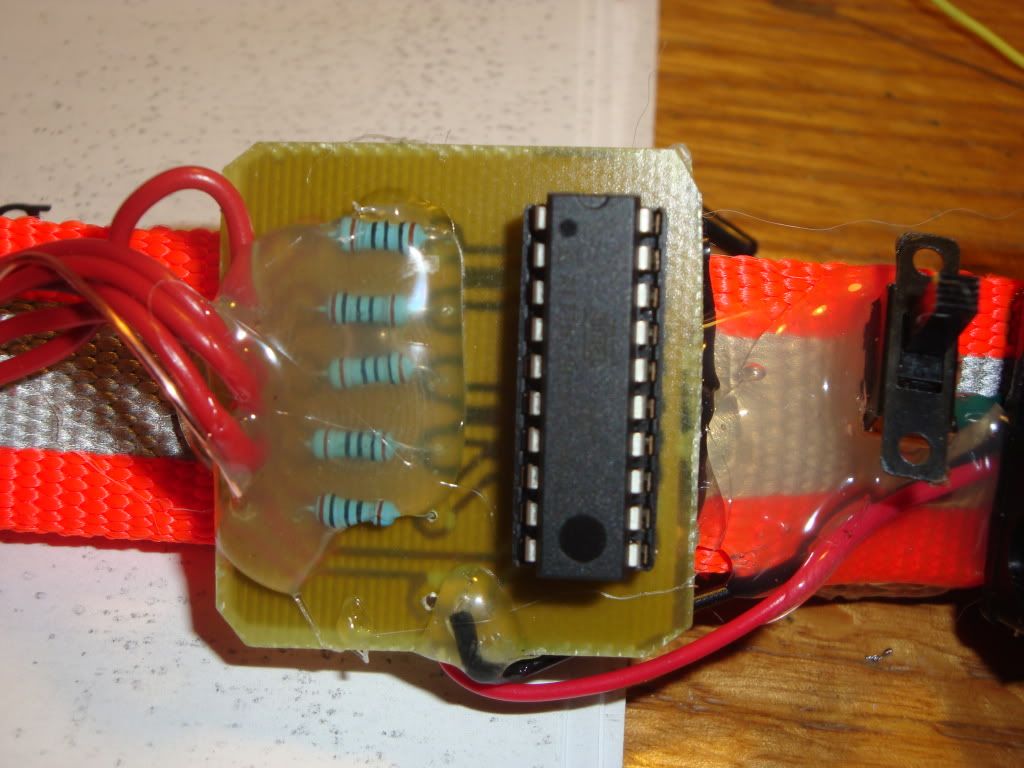

LED Dog Collar

So this is a pretty simple project, but I thought it was a clever idea. I have 2 dogs, a lab and a lab mix. The lab "Sunshine" likes to runaway a lot if we let her outside at all. She always comes back, but we can't find her whenever she leaves. This worries us sometimes because we don't want a car to hit her, especially at night. Anyways, my idea came from this that I could make some type of collar that at least at night, would make her more visible.

Thus came the idea of a LED dog collar. Now, this basic one has to be turned on and off (which means that I would have to let her out on purpose to use it) but it is just a prototype. I have ideas about how to make it automatically turn on, but more on that later.

So the collar runs off an Atmel AVR ATTINY2313. It has 5 blue LEDs, and is powered by 3 AAA batteries. I also etched a custom circuit board (toner transfer method) and then covered most of the components in hot glue. The LEDs and all the wires on the collar are also mounted using hot glue. Now I definitely could have used a smaller avr, but the attiny2313 was the only micro I had lying around other than my bigger ATMEGA 328 from the arduino which I used as an ISP to program the tiny. The code is very simple, written in C, it just does several different strobe and "police light" patterns. Like I said before the device has a switch to turn it on and off.

Here are some photos and a video of it in action:

Now I was talking about the switch before, how it seems kind of pointless for the original intent of the collar (in case my dog runs away). So I was thinking, how do I trigger the LED collar to come on when my dog is outside? Well, I thought one idea, since it is winter right now, it is much colder outside. So if I hooked a temperature sensor up to the MCU, I could cause low temperatures to activate the LEDs. Just an idea, still a work in progress.

Video:

Thus came the idea of a LED dog collar. Now, this basic one has to be turned on and off (which means that I would have to let her out on purpose to use it) but it is just a prototype. I have ideas about how to make it automatically turn on, but more on that later.

So the collar runs off an Atmel AVR ATTINY2313. It has 5 blue LEDs, and is powered by 3 AAA batteries. I also etched a custom circuit board (toner transfer method) and then covered most of the components in hot glue. The LEDs and all the wires on the collar are also mounted using hot glue. Now I definitely could have used a smaller avr, but the attiny2313 was the only micro I had lying around other than my bigger ATMEGA 328 from the arduino which I used as an ISP to program the tiny. The code is very simple, written in C, it just does several different strobe and "police light" patterns. Like I said before the device has a switch to turn it on and off.

Here are some photos and a video of it in action:

Now I was talking about the switch before, how it seems kind of pointless for the original intent of the collar (in case my dog runs away). So I was thinking, how do I trigger the LED collar to come on when my dog is outside? Well, I thought one idea, since it is winter right now, it is much colder outside. So if I hooked a temperature sensor up to the MCU, I could cause low temperatures to activate the LEDs. Just an idea, still a work in progress.

Video:

Subscribe to:

Posts (Atom)